We must first understand the true face of lithium batteries

While recognizing battery safety performance testing equipment, we must first understand the true face of lithium batteries!

As we all know, power battery is the core technology of electric vehicles. Compared with traditional lead-acid batteries and nickel-metal hydride batteries, lithium-ion batteries are the main development direction of current power batteries because of their high specific energy, high specific power, easy realization of rapid charging and deep discharge, and long life.

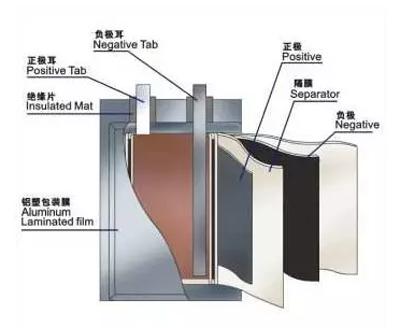

In fact, these performance of lithium ion battery is closely related to its packaging form. In this article, we will explain in detail the packaging forms of lithium-ion batteries and look at the advantages and disadvantages of different technical routes.

According to the different shell of the cell, lithium ion battery can be divided into hard shell and soft shell. The material of hard shell is mainly steel shell and aluminum shell, while the soft package is aluminum plastic composite film material. Among them, the hard shell is divided into cylindrical and square according to the arrangement of the positive and negative polar plates inside.

From this, we can get three types of packaging of the current mainstream lithium-ion batteries, namely cylindrical, prismatic, and pouch (also called polymer battery in some places).

1. Cylindrical batteries, because of their mature technology and favored , have attracted much attention;

2. Prismatic battery, because of its good safety, is also one of the mainstream technical routes;

3. The development of pouch battery has benefited from the development trend of consumer electronics towards smaller, lighter and thinner.

GESTER in 1997, has a vast experience in battery pack tester design and manufacture and specializes in Battery Testing Equipment.

Contact Us