About The Battery External Short Circuit Test Requirements

UN38.3 certification

Keep the test environment temperature stable at 57±4℃, so that the surface temperature of the battery cell or battery sample reaches 57±4℃.

The positive and negative electrodes of the sample were short-circuited with a total resistance loop less than 0.1Q2, and the surface temperature of the sample was restored to 57±4°C and kept in the short-circuited state for more than 1 hour.

The cell or battery must be observed for 6 hours to draw conclusions.

Result: During the test and within 6 hours thereafter, the surface temperature of the cell or battery sample did not exceed 170°C, and there was no disassembly, no cracking, and no fire.

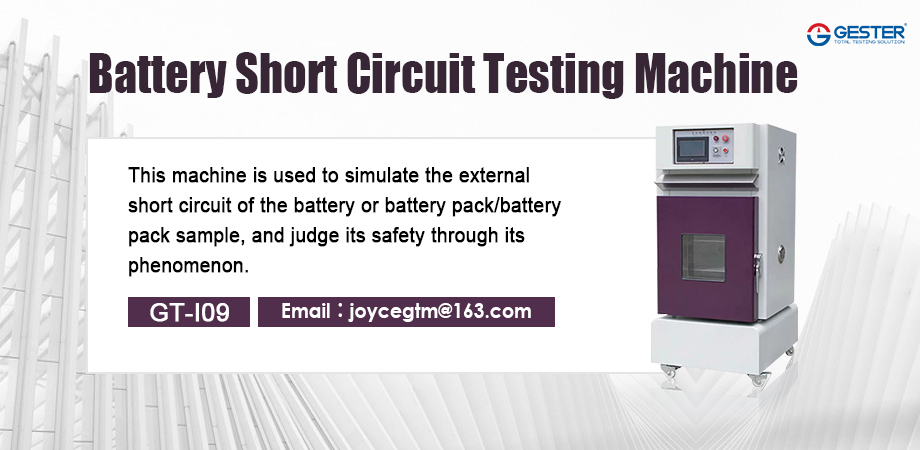

GESTER Battery Testing Machine is specialized in sales and manufacturing for Battery Short Circuit Tester.

Application

The battery short-circuit tester is designed according to the requirements of various battery short-circuit test standards. According to the standard, the short-circuit device must meet the internal resistance range of 80mΩ±20 or ≤10mΩ to obtain the maximum short-circuit current required by the test. This Battery Testing Machine is used to simulate the external short circuit of the battery or battery pack/battery pack sample, and judge its safety through its phenomenon.

Battery Short Circuit Tester standard

GB 31241-2014, UL 2540-2013, UL 1642, UL 2054, UN38.3, IEC62133-2017

Contact Us